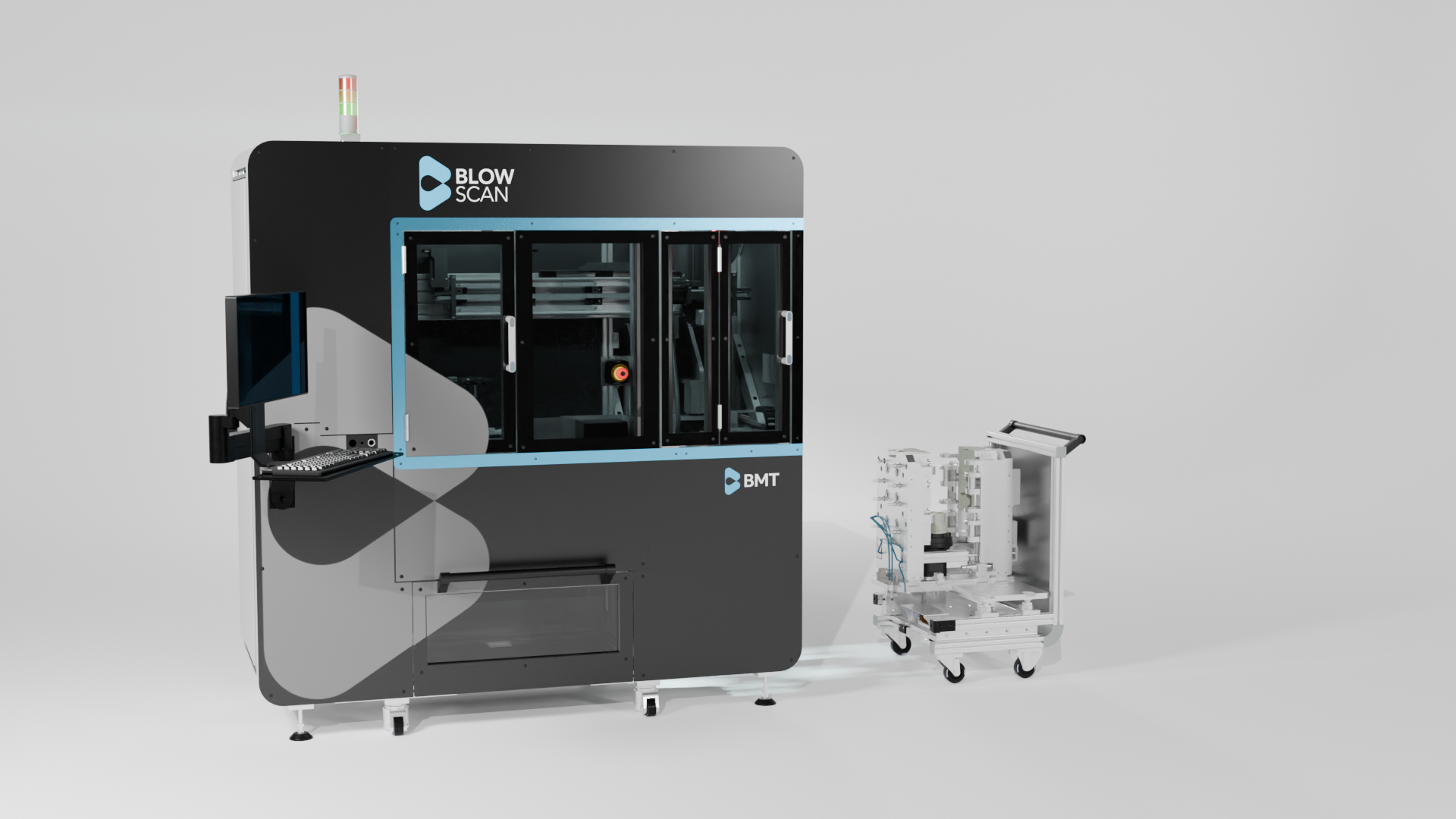

See our new BLOWSCAN render!

We’ve released a new render showing how BLOWSCAN works — our lab-based stretch blow moulding machine that enables detailed analysis of PET and bio-based materials.

Watch the render here: BLOWSCAN - Render

BLOWSCAN helps packaging innovators:

Test and validate PET & bio-resin preforms at lab scale

Optimise bottle design before full production

Troubleshoot defects like haze, pearlescence, and variation in bottle performance

For the full story, visit our product page: Explore BLOWSCAN

PETnology Europe 2025

Dr Josh Turner, Head of Materials Characterisation, and Dr Jude Cameron, Project Lead, will present at PETnology Europe 2025 on the BMT Way: Smarter Solutions for Sustainable Packaging.

Our approach — Measure, Digitise, Execute — moves beyond the packaging industry’s reliance on trial-and-error, empowering partners to make data-driven decisions. By combining:

Cutting-edge simulation

AI-driven insights

Hands-on engineering expertise

We help packaging innovators to:

Reduce material waste through efficient virtual prototyping

Lower the risks of adopting new, sustainable materials

Accelerate product development for future-ready packaging

NAFEMS World Congress 2025 - Best Presentation Award

We’re incredibly proud that Dr. Ross Blair received the Best Presentation Award at this year’s NAFEMS World Congress in Austria, representing BMT in the global spotlight.

His award-winning presentation,

“Measure, Digitise, Execute: Streamlining Sustainable Packaging Design,”

was recognised among top leaders in engineering simulation and sustainable product design.

This prestigious recognition is a testament to the dedication and innovation of our full team:

Dr. Ross Blair, Dr. Dimitris Papadimitrakis, Reece Armstrong, Alexander McKee and Professor Gary Menary

Our team is pushing the boundaries of sustainable packaging by applying a unique Measure, Digitise, Execute methodology. Using advanced simulation technology, we help businesses:

Minimise packaging waste

Improve performance and durability

Meet sustainability goals through smart design

This achievement reflects our mission to deliver data-driven, eco-conscious solutions in packaging and manufacturing.

Article Published - Measure the Shift

Our article in the May edition of PETplanet insider dives into how digital simulation and advanced material modelling are transforming preform and bottle development.

From virtual validation to physical formation, our Smart Prototyping approach helps teams streamline design, reduce waste, and move faster with confidence.

Measure. Digitise. Execute.

That’s how we’re supporting more sustainable PET packaging, from prototype to production.

Read the full article here

Catch up on the full BMT Bottle Series

Plastics Recycling Show Europe 2025

Our Head of Material Characterisation, Dr Josh Turner, will be in Amsterdam on 1–2 April for the Plastics Recycling Show Europe (PRSE).

If you’re aiming to:

Fast-track rPET adoption in packaging

Reduce defects and production issues

Maintain clarity and quality in recycled plastics

Josh is the expert you’ll want to speak with.

Article Published - Why speed alone isn’t enough?

Still relying on trial-and-error for packaging design?

In PETplanet Insider, we showcased how Smart Prototyping with BLOWSCAN—combined with 3D printed moulds—lets converters move confidently from virtual validation to real-world results.

By testing and refining bottle designs before full-scale production, leading packaging teams are:

Streamlining product development

Reducing material waste

Lowering production costs

Accelerating packaging innovation

Don’t guess. Validate smarter with BLOWSCAN.

Find out more about our SMART Prototyping process.

Article Published - From Haze to Clarity

The transition from virgin PET to rPET in stretch-blow moulding is far from plug-and-play. Recycled PET often exhibits lower intrinsic viscosity, increased variability in crystallinity, and reduced strain hardening. These changes significantly affect preform stretchability, wall distribution, and bottle clarity.

Manufacturers must adapt their process settings to accommodate:

Blow-moulding temperatures: rPET typically requires tighter control due to its thermal sensitivity.

Stretch ratios: The strain-hardening behaviour of rPET lags behind virgin PET, which can cause early pearlescence if not properly managed.

Residence time & drying: rPET is more hygroscopic and must be thoroughly dried to prevent hydrolytic degradation during processing.

Tools like BLOWSCAN and Digital Image Correlation (DIC) can quantify these differences and help optimise the process window for rPET materials — ensuring product performance is maintained despite material variability.

Read our article here.

Smart Sustainable Plastic Packaging Challenge - Presentation

Dr Ross Blair, our Head of Simulation, presented at the Smart Sustainable Plastic Packaging Challenge Celebration Event, hosted by Innovate UK and UKRI

Ross shared insights on how digital innovation and simulation at BMT are driving smarter, more sustainable packaging solutions.

Article Published - Beyond the surface

Beyond the Surface: Optimising rPET Heating

In our article in PETplanet Insider, we look at why surface temperature isn’t enough — and how getting the preform heating profile right is key to consistent bottle quality. THERMOSCAN measures both internal and external temperatures, giving a full picture of how each preform responds to heat. This helps improve oven setup, reduce defects, and manage rPET variability with more confidence.

Read the article: Beyond the Surface: Mastering Preform Heating for rPET Success

QUB Engineering Leadership Programme

BMT is proud to be invited to host a special session for Queen’s University Belfast’s Engineering Leadership Programme (ELP).

Our CAE engineers, Alexander McKee and Reece Armstrong—both graduates of QUB’s School of Engineering—will deliver insights on:

What BMT does and the positive impact of our engineering work

Sustainability in plastic packaging, and why it matters for the future

Leadership and innovation in engineering and industry

By sharing expertise in sustainable engineering solutions and leadership, we’re supporting the next generation of engineering leaders and innovators.