Simulation

What’s peace of mind worth?

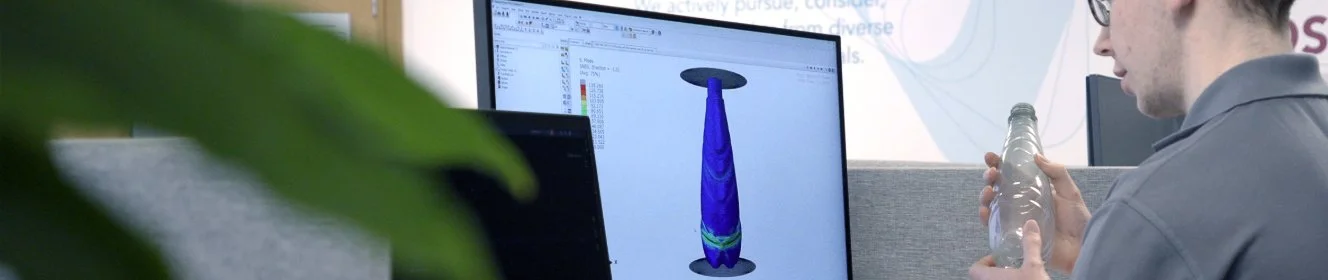

Simulate it before you build it. No surprises. No setbacks. Just smart decisions, made early.

For visionary engineers and R&D innovators, sustainability champions, and brand leaders driving faster, smarter packaging breakthroughs.

Have a challenge?

Let’s simulate the solution.

Design better, faster

-

Virtual prototyping for process, thickness, weight, and performance evaluation

Advanced lightweighting to optimise preform design for weight, performance, and efficiency

Bottle structural design to meet functional and performance specifications

Preform harmonisation across product portfolios for consistent quality

Build trust through precision

-

Material model calibration for high-fidelity simulation results

Material substitution analysis to compare processability and performance

Accurate simulation-driven performance validation before physical trials

Data-driven design refinement using simulation insights

Drive efficiency & sustainability

-

Lightweight designs to reduce material usage without compromising strength

Process optimisation to cut waste and improve energy efficiency

Material selection for sustainability while maintaining performance

Simulated testing to avoid unnecessary production trials

Enable in-house capability

-

Training in simulation, AI, and stretch blow moulding (SBM) best practices

Tailored workshops for internal teams on digital prototyping and process optimisation

Implementation of digital tools to enhance internal R&D capacity

Ongoing application support to ensure smooth operations

Partner for long term impact

-

Process troubleshooting and optimisation support

Bespoke solutions for modelling, simulation, and process enhancement

Development of scalable, modular digital solutions for evolving needs

Strategic collaboration to maintain performance and cost benefits over time

Why Simulation?

Simulation

Cut costs, lead times and materials with BMT simulation.

Get results in hours

Build smarter and faster

Get early insights

An optimised process

v

Wasted efforts, incurs extra costs and environmentally detrimental.

Trial and error

Extra testing

Late issues

Additional labour

Slow to scale

Don’t get left behind. Simulate

Our simulation and AI capabilities turn failure into foresight, solving problems before they're real.

Why BMT?

Trusted by PepsiCo to set the benchmark in packaging innovation.

Gold standard for innovation.

Science, software, and sustainability combined.

Recognised for Excellence

NAFEMS World Congress 2025 Best Presentation Award for sustainable packaging design.

Trusted by Fortune 500 companies

We help the world’s biggest packaging brands cut plastic and stay ahead.

Backed by the UK Government

Awarded Innovate UK grants to advance AI and simulation for sustainable manufacturing.

30 years, 50 publications

Decades of experience, backed by academic rigour and research partnerships — including QUB.

SIMULATION FAQ’S

-

Just an idea and a goal. We can work with CAD files, physical samples, sketches — whatever you have. Once we understand what you're trying to achieve, we’ll guide you through the rest. No complex onboarding or setup required.

-

Most projects deliver results in 1–3 weeks, depending on complexity. We prioritise speed without sacrificing accuracy — so you can make decisions fast and move with confidence.

-

We specialise in rigid and semi-rigid plastic packaging — bottles, jars, closures and more. But our tools and approach also apply to flexible films, laminated structures, and even novel materials.

-

Our simulations have been validated against lab data and real-world outcomes — many clients now use them to reduce physical tests, not replace them outright. Think of simulation as a smart filter: run more virtual trials, and only physically test what’s worth prototyping.

-

Absolutely. We often act as an extension of internal teams — providing extra horsepower, niche expertise, or helping upskill your people in simulation tools.

-

No installations needed. We run everything on our end and deliver results in the format that works best for you — from reports and videos to CAD-ready geometry.

-

Pricing depends on scope, but our clients typically save money by reducing failed prototypes, material usage, and time to market. We’re happy to provide a quick quote based on your goals.

-

Yes — we offer training, workflow setup, and support to help you integrate simulation into your internal process. Whether you're starting from scratch or levelling up, we’ve got you covered.

-

Definitely. We’ve helped multiple clients demonstrate simulation’s impact on cost, speed, and sustainability. We can provide case studies, metrics, and framing to help make the case inside your organisation.