SMART Prototyping

Fast Prototypes, SMART Decisions?

Go from concept to physical bottle prototypes in just five days - validate faster, iterate smarter and reduce time to market

Simulation driven

Mould-on-demand

Accelerated workflow

Real world validation

Time critical

Prototyping

Turn concepts to clarity

Start now

Transform your concept into a tangible prototype in just five days.

Test fit, form, and function earlier—so you can move forward with confidence.

Sketch Monday Product Friday

Design Smarter with Simulation

Monday to Wednesday

We begin by creating a digital simulation, running virtual tests to explore and optimise the processing window before moving into production.

Precision moulds, Printed fast

Monday to Wednesday

In parallel with simulation, we design and 3D print precision moulds—allowing us to blow early prototype bottles within just three days.

From prototype to physical validation

Wednesday to Friday

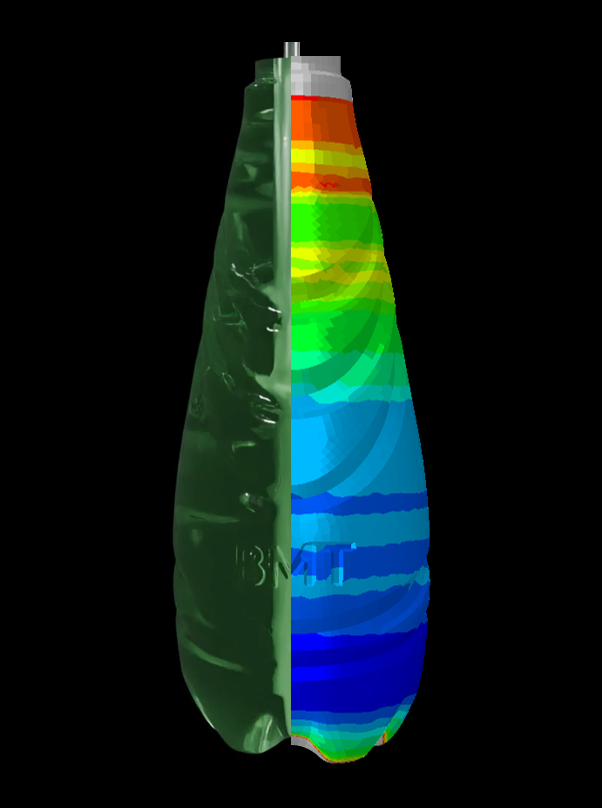

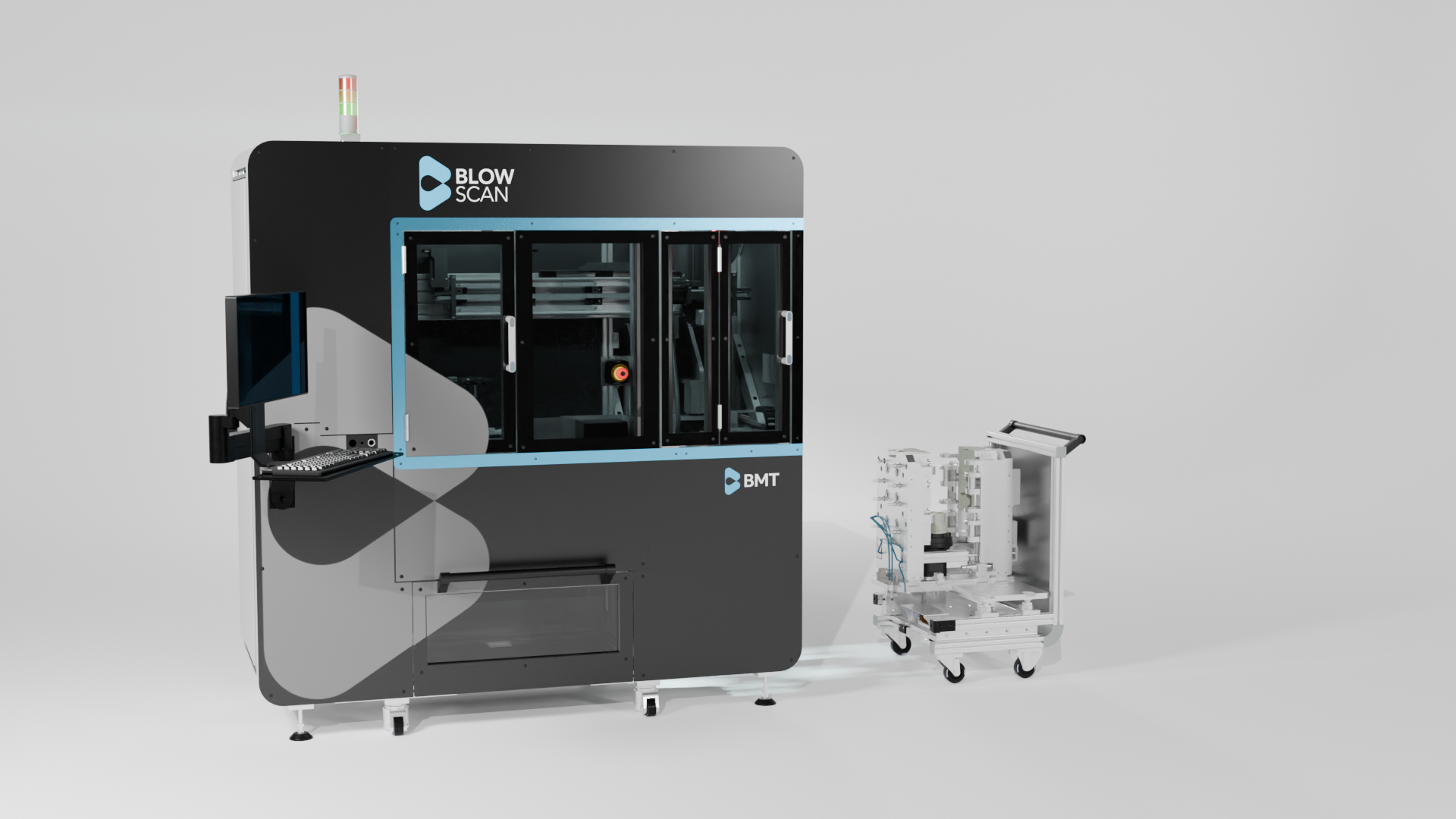

Using BLOWSCAN early prototypes are blown to confirm the processing window, followed by production bottles for physical testing and validation.

Why SMART Prototyping?

Cut costs, lead times and materials with BMT’s SMART prototyping approach.

SMART Prototyping

Fewer iterations, faster results

Custom 3D-printed moulds on demand

Prototypes ready by Friday

Quick changes and fast re-runs

Encourages experimentation without delay

Quicker qualification for market scaling

v

Trial and error

Wasted efforts, incurs extra costs and environmentally detrimental.

Several weeks to months

Long cycle times

Long leadtimes for hard tooling

Repeated tooling, wasted materials

Delayed testing and approvals

Penalized failure with time and cost

Accelerate your bottle design

Say goodbye to long lead times. From initial sketch to functional prototype in just five days, our process speeds up development and clears the path to market.

Why BMT?

Trusted by PepsiCo to set the benchmark in packaging innovation.

Gold standard for innovation.

Science, software, and sustainability combined.

Recognised for Excellence

NAFEMS World Congress 2025 Best Presentation Award for sustainable packaging design.

Trusted by Fortune 500 companies

We help the world’s biggest packaging brands cut plastic and stay ahead.

Backed by the UK Government

Awarded Innovate UK grants to advance AI and simulation for sustainable manufacturing.

30 years, 50 publications

Decades of experience, backed by academic rigour and research partnerships — including QUB.

PROTOTYPING FAQ’S

-

Just an idea and a goal. We can work with CAD files, physical samples, sketches — whatever you have. Once we understand what you're trying to achieve, we’ll guide you through the rest. No complex onboarding or setup required.

-

Typically 5 days once the bottle design has been received along with the physical preforms. SMART prototyping implements a parallel workflow where simulation, 3D printing and bottle production all come together to reduce the prototyping time while increasing the production confidence

-

BMT will complete the bottle quality and performance validation internally with every project. This will be at the customers request and uses BMT's suite of equipment and instrumentation to evaluate the bottles produced. Customers will receive a quantity of formed bottles that are suitable for consumer testing along with their own performance testing should they desire.

-

Along with physical bottles, the customer will receive an information pack that provides insight into the blowing capabilities of the preform-to-bottle pair i.e. temperature window, blowing parameters, forming limitations. This recipe can be then used for scale-up to pilot trials or even to production. In addition, they will receive a preformance validation report as per their request to ensure that the bottles formed are in spec.

-

This SMART prototyping is currently only available for the injection stretch blow moulding process. We cover all grades of PET and also have insights into other non-PET materials (Tritan, bio-based, polyolfins)

-

Pricing depends on scope, but our clients typically save money through 3D printed moulds and reduced time to market. We’re happy to provide a quick quote based on your goals.

-

The purpose of SMART prototyping is to not only produce consumer-ready bottles quickly, but also provide unrivalled knowledge into the formation process itself through valuable data. This reveals the critical information required that can inform full-scale production how they can succeed faster and more reliably.

-

Yes—SMART Prototyping delivers measurable value across time, cost, and risk reduction. Numerous benefits delivered with the process include increased speed to market, fewer design iterations (reduced costs), informed decision making, increased agility and an increase in competitive advantage

-

SMART prototyping implements a parallel workflow that employs specialised BMT teams to reduce the prototyping time significantly. This approach reveals early insights that reduces the number of iterations required and eliminates costly mould tooling. The substantial reduction in prototyping time, along with smarter decision making allows for design iterations to be tested faster and with more confidence.